NuCreamer™

Non Dairy Creamer For Anti-Acid Beverage

Setting the Standard

How does the non-dairy creamer benefit Anti acid beverage?

Non-dairy creamer helps stabilize anti-acid beverages by improving mouthfeel, masking bitterness, and preventing separation of ingredients. It also enhances creaminess without curdling in acidic conditions.

NuCreamer™

For Anti Acid Beverage

Non-dairy creamer

Stability · Creaminess · Bitterness masking · Mouthfeel enhancement · Acid resistance

This ingredient stabilizes formulations by resisting curdling in acidic conditions. It delivers a smooth, creamy texture that enhances mouthfeel while masking bitterness. Its acid resistance ensures consistent quality, making the beverage more palatable and enjoyable..

organic brown rice protein manufacturer, organic brown rice protein factory,organic brown rice protein isolate supplier, organic brown rice protein powder wholesaler,organic brown rice protein bulk sale, organic brown rice protein distributor,organic brown rice protein exporter importer,organic brown rice protein stock,TC,COI,NOP,Europe,Germany, UK,Australia,Thailand,New Zealand,USA, China

organic brown rice protein manufacturer, organic brown rice protein factory,organic brown rice protein isolate supplier, organic brown rice protein powder wholesaler,organic brown rice protein bulk sale, organic brown rice protein distributor,organic brown rice protein exporter importer,organic brown rice protein stock,TC,COI,NOP,Europe,Germany, UK,Australia,Thailand,New Zealand,USA, China

Features For Anti Acid Beverage

Of NuCream™ Non-Dairy Creamer

Specification Information

| Item | Specification |

|---|---|

| Raw Material | Vegetable Oil |

| Flavor | creamy/milky |

| Color | White to light cream |

| Moisture | Max5.0% |

| Lead(Pb) | ≤1.0mg/kg |

| Arsenic(As) | ≤0.5mg/kg |

| Free flowing | Good |

| Flavor/Odor | Characteristic |

| Foreign substance(Impurities) | None |

| Aerobic Plate Count | ≤10000cfu/g |

| Mould | ≤50cfu/g |

| Coliform | ≤40cfu/g |

| Salmonclla | Negative |

organic brown rice protein manufacturer, organic brown rice protein factory,organic brown rice protein isolate supplier, organic brown rice protein powder wholesaler,organic brown rice protein bulk sale, organic brown rice protein distributor,organic brown rice protein exporter importer,organic brown rice protein stock,TC,COI,NOP,Europe,Germany, UK,Australia,Thailand,New Zealand,USA, China

| Item | Information |

|---|---|

| Package | 25kg, 1kg, 500g, 300g, 200g, 150g, 30g, 18g, or customer-made |

| Container Loading | Package in 25 kg: 20’ container loads 15MT; 40’ container loads 26MT. |

| Facility | Germany spray drying equipment |

| Certificate | ISO, HACCP, FDA, HALAL, KOSHER |

| Lead time | 14 days lead time. By sea, by train. |

| Delivery & Service | We ensure timely delivery, reliable service, and take full responsibility for every product and customer. Our goal is to achieve complete customer satisfaction through exceptional service. |

Shipping Information Timely and Reliable

Experience . Quality .Support. Trusted Source for You

Four Checks, One Standard Tested Thoroughly, Delivered Confidently

→

→

→

Sub-categories NuCream™ Non-Dairy Creamer

1. Q: Can you help with international shipping and customs clearance?

A: Yes. We handle the entire logistics process, including international shipping and customs documents, via our reliable freight partners. Just confirm your delivery details—we’ll take care of the rest. We ship by sea or train, with a standard lead time of 14 days.

2. Q: Can I get a sample?

A: Yes, we offer free samples for testing. We only ask that you cover the courier cost to your location.

3. Q: Can I get a customized non-dairy creamer for my application?

A: Absolutely. Our experienced R&D team can formulate non-dairy creamers tailored to your product’s needs—whether you require specific fat content, solubility, flavor, or functionality.

4. Q: What is your minimum order quantity (MOQ)?

A: MOQ varies depending on product and packaging, but we support flexible quantities to help customers start small and scale up when ready.

Q&A NuCream™ Non Diary Creamer

5. Q: What packaging options are available?

A: We offer a wide range of packaging sizes: 25kg, 1kg, 500g, 300g, 200g, 150g, 30g, 18g, or customized according to your needs.

6. Q: How much product fits in a container?

A: For 25kg bags: a 20-foot container holds 15 metric tons, while a 40-foot container holds up to 26 metric tons.

7. Q: How do you ensure product quality?

A: All products undergo a strict four-step quality control process: Raw Material Inspection,In-Process Inspection,Final Inspection,Outgoing Inspection.

8. Q: What kind of service can I expect?

A: We are committed to timely delivery, consistent quality, and responsible service. Every order is treated with care, and our goal is to ensure complete satisfaction for each customer.

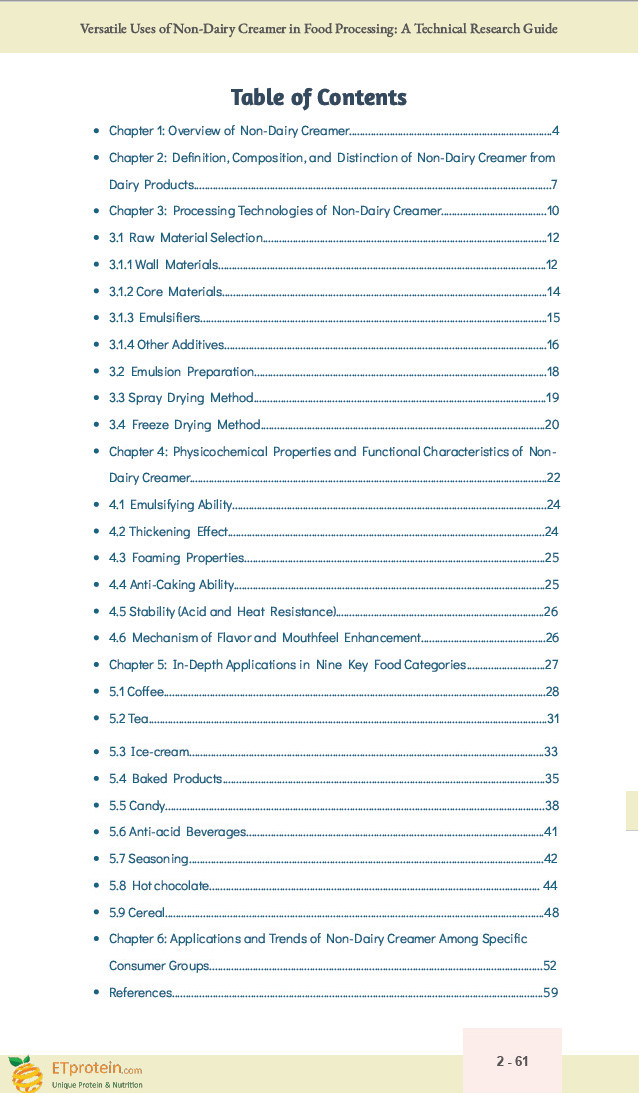

Versatile Uses of Non-Dairy Creamer in Food Processing: A Technical Research Guide,

63 pages

E BOOK written by ET Protein R&D Team

Experience the complete journey Non dairy creamer with our comprehensive e-book, passionately crafted by the experts at ETprotein. Dive into the science, innovation, and dedication behind our breakthrough product. We’re thrilled to share this wealth of knowledge with you for free! Get your copy today and join us in revolutionizing health and wellness.

L(+)-Ergothioneine EGT Cosmetic 99.9% Chinese Supplier Factory Manufacturer,L(+)-Ergothioneine manufacturer,L(+)-Ergothioneine supplier,L(+)-Ergothioneine factory,L(+)-Ergothioneine laboratory,L(+)-Ergothioneine ,manufacturer,L(+)-Ergothioneine bulk sale,L(+)-Ergothioneine wholesale,L(+)-Ergothioneine distributor,L(+)-Ergothioneine importer,L(+)-Ergothioneine exporter,L(+)-Ergothioneine warehouse, EGT manufacturer,EGT supplier,EGT factory,EGT laboratory,EGT ,manufacturer,EGT bulk sale,EGT wholesale,EGT distributor,EGT importer,EGT exporter,EGT warehouse, China, UK, USA,Canada,Australia, New Zealand, Middle east,American,Brazil, Chile,Europe,Germany, France,Netherlands,Italy,Spain,Austria

1. E.F E-A, El-Damaty E, M.A E-W. Effect of using Non-dairy creamer as a fat substitution on quality properties of cake [J]. Egyptian Journal of Chemistry, 2023, 66(3): 69-78. 2. Liu X, Xu W, Wang W, et al. Physicochemical properties and feasibility of coconut oil-based diacylglycerol as an alternative fat for healthy non-dairy creamer [J]. Food Chemistry: X, 2023, 19: 100749.

3. Wang B, Liu J. Trans-Free Nondairy Creamer Prepared from Enzymatic Interesterification of Soybean Oil and Fully Hydrogenated Soybean Oil [J]. Journal of Food Process Engineering, 2014, 37(4): 339-348.

4. Rabišková M, Valášková J. The influence of HLB on the encapsulation of oils by complex coacervation [J]. Journal of Microencapsulation,1998, 15(6): 747-751.

5. Renata V. T, Carlos R F, Grosso M D. Influence of emulsion composition and inlet air temperature on the microencapsulation of flaxseed oil by spray drying [J]. Food Research International, 2011 (44):282-289

6. Frascareli E C, Silva V M, Tonon R V, et al. Effect of process conditions on the microencapsulation of coffee oil by spray drying [J]. Food and Bioproducts Processing, 2012, 90(3): 1-12

7. Gharsallaoui A, Roudaut G, Chambin O, et al. Applications of spraydrying in microencapsulation of food ingredients: An overview [J].Food Research International, 2007, 40 (9): 1107-1121

8. Kalaya L, Tida M, Saiwarun C. Microencapsulation of Macadamia oil by spray drying [J]. Procedia Food Science, 2011(1): 1660-1665

9. Garcia E, Gutierrez S, Nolasco N, et al. Lipid composition of shark liver oil: effects of emulsifying and microencapsulation processes [J]. European Food Research and Technology, 2006, 222 (5-6): 697-701

10. Martin C A, Milinsk M C, Visentainer J V, et al. Trans fatty acidforming process in foods: a review [J]. Anais da Academia Brasileira de Ciências, 2007, 79 (2): 343-350

11. Petrut R F, Danthine S, Blecker C. Assessment of partial coalescence in whippable oil-in-water food emulsions [J]. Advances in Colloid and Interface Science, 2016, 229: 25-33.